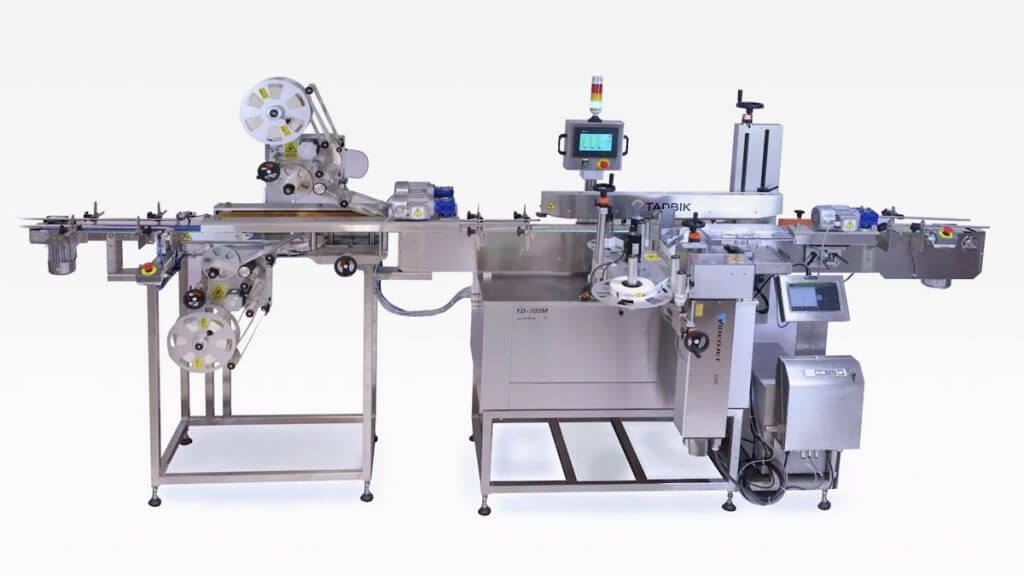

Tadbik Systems is proud to introduce its new and improved label applicator.

After designing and installing over 4700 robust label applicators worldwide, Tadbik Systems is excited to launch the new generation of label applicators.

Still just as robust and durable, the new label applicator is now modular and position-independent, offering greater flexibility. Our advanced label applicator helps enhance overall operational excellence at the production floor.

“Our 25 years of experience was put into the new label applicator”, says Tal Sitbon, CEO of Tadbik Systems. “The new servo/ stepper-motorized mechanism can be utilized with an external feeder for non-stop operation at a higher speed. Suitable for all industries, Tadbik System’s new Label Applicator provides greater value to the operator and to the factory, regardless of its sector and core activity”.

Feature enhancement include:

-

- New Label Applicator can be integrated seamlessly into the existing, already operative Tadbik System labeling machines

- New Label Applicator can operate with an external feeder for non-stop operation at a higher speed

- Delivery models: a standalone unit or as an integral part of the labeling machine

- Modularity enables a wide range of printers – laser printers, thermal transfer and inkjet

- Modularity enables different types of sensors and vision & inspection devices utilization

- Stepper / servo-motorized mechanism

- More compact design

- Simpler mechanics

- Intuitive and operator-friendly

- Simple and short maintenance – ease of operation and downtime reduction results in better OEE

- Upgraded film release handle

- Enhanced collecting mechanism

For more information about our Shrink Sleeve Label Machine