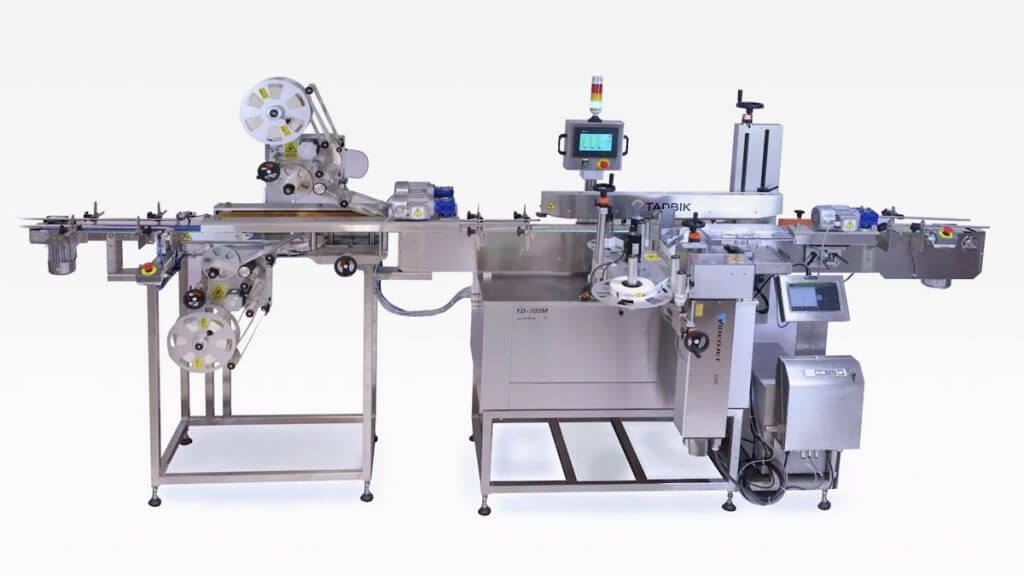

A pharmaceutical company who is a leader in global healthcare contacted Tadbik Systems to design a unique sterile tab debagging system.

The main challenges were to create a machine that complies to the most stringent standards of sterile, pharmaceutical operation, as well as a very complex and a high nylon wrapping variance.

Tal Sitbon, CEO of Tadbik System explains:

“The machine we created is an Automatic Tab Debagging System, designed in a custom-made engineering project. The main considerations were utmost sterile environment, safety and precision, which are standard requirements for sterile pharmaceutical operations. The key challenge was to design a robust system that handles successfully the vast range of tab’s nylon wrapping variability.

Our R&D team was able to address an unmet need, which was to automate the debagging process in a cost-effective way to maintain peak production rates and minimize downtime – all while improving efficiency”.

Tadbik System’s Tab Debagging System is capable of debagging sterile tabs, fed by a designated machine also provided by Tadbik Systems. It requires no operator intervention.

The machine operation consists of three main modules:

- Main conveyor carries the tab through different stations

- A unique, tailor-made system for opening and cutting of the tabs’ nylon wrapping

- A separating mechanism to separate the tab from its nylon wrapping and transfer module to send the tab to the sterile room

- Each and every module meets the highest safety and quality standards of the pharmaceutical industry.